Categories

- Alloys (4)

- Brochures (5)

- Metal Part Casting (3)

- Metal Sprayed Moulds (10)

- Nylon Vacuum Casting (2)

- Photo overview (4)

- Prototyping Museum (7)

- Selective Laser Melting (SLM) (5)

- Sheet Metal forming (1)

- Vacuumcasting (13)

5 of the most-read articles

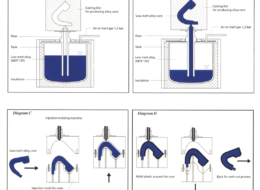

3 Prototype moulds all produced in a single day using MCP MetaLSpray Mould Technology : All plastic parts produced with an MCP Prototyping Injection Moulder, Type 25P

For years experts have recognized the advantage of metal spraying of moulds with MCP Alloys. Long delivery times for moulds, increasing costs and the necessity to check new plastic products… [Continue Reading]

MCP supplies Materialise in Leuven, Belgium with one of the largest vacuum casting machines ever built. The machine will produce plastic and wax prototypes up to 13 kg in weight… [Continue Reading]

Fusible Core Technology with MCP Low Melt Alloys “Make The Impossible” Properties and Uses of MCP Low Melting Point Alloys explained in the 27-sided Powerpoint Presentation with examples of MCP… [Continue Reading]