Categories

- Alloys (4)

- Brochures (5)

- Metal Part Casting (3)

- Metal Sprayed Moulds (10)

- Nylon Vacuum Casting (2)

- Photo overview (4)

- Prototyping Museum (7)

- Selective Laser Melting (SLM) (5)

- Sheet Metal forming (1)

- Vacuumcasting (13)

5 of the most-read articles

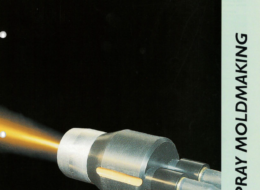

MCP/TAFA makes a wide range line of energy-efficient thermal spray coating systems for a wide spectrum of industries. Everything from manually operated units to a totally automatic turnkey systems are… [Continue Reading]

Please click to enlarge the Images.

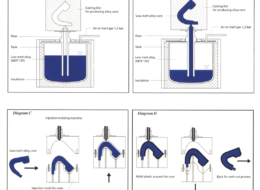

Fusible Core Technology with MCP Low Melt Alloys “Make The Impossible” Properties and Uses of MCP Low Melting Point Alloys explained in the 27-sided Powerpoint Presentation with examples of MCP… [Continue Reading]

Tools and Parts with MCP 137 Low Melt Alloys published by MCP-HEK GmbH, Germany

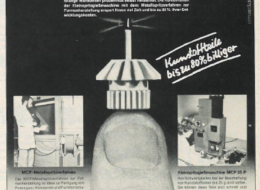

Recognising the requirement for quick tooling solutions, MCP introduced a complete low cost package system for producing moulds for: Plastic and Wax Injection Thermoforming Polyurethane –Bumpers and Shoes Hand Lay… [Continue Reading]