Categories

- Alloys (4)

- Brochures (5)

- Metal Part Casting (3)

- Metal Sprayed Moulds (10)

- Nylon Vacuum Casting (2)

- Photo overview (4)

- Prototyping Museum (7)

- Selective Laser Melting (SLM) (5)

- Sheet Metal forming (1)

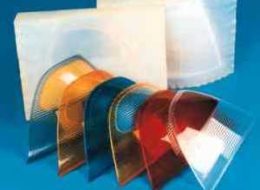

- Vacuumcasting (13)

5 of the most-read articles

A total solution package, MCP Metal Part Casting System literally takes the heat out of castings metals. A new type of automotive gearbox housing requires castings with a multitude of… [Continue Reading]

HEK GmbH is a member company of the 60 year old MCP Group, one of the oldest producers of low melting alloys worldwide. Low melting alloys were traditionally used in… [Continue Reading]

Recognising the requirement for quick tooling solutions, MCP introduced a complete low cost package system for producing moulds for: Plastic and Wax Injection Thermoforming Polyurethane –Bumpers and Shoes Hand Lay… [Continue Reading]

Please click to enlarge the Images.

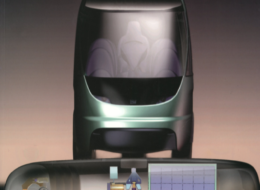

We will also be presenting the SLM – Selective Laser Melting Process with the MCP RealizerSLM. This world class, innovative process has the widest range of applications for producing body… [Continue Reading]